Fluke MDA-510 and MDA-550 – The Future of Motor Drive Troubleshooting

Troubleshooting motors, drives, pumps, and compressors can be difficult and perplexing. The complexities of these systems necessitate a thorough understanding and an acute eye for detail. However, with the introduction of novel equipment such as the Fluke MDA-550 Motor Drive Analyzer, the process is becoming simpler, more efficient, and accessible to a wider range of specialists.

Motor drives, also known as variable speed drives (VSD), variable frequency drives (VFD), and adjustable speed drives (ASD), are critical components of motor-powered equipment such fans, pumps, and compressors. They adjust the speed of a motor to meet the needs of an application, which is critical in many sectors. Motor drives are the unsung heroes who keep our world going in industries such as manufacturing, HVAC, automotive, and energy.

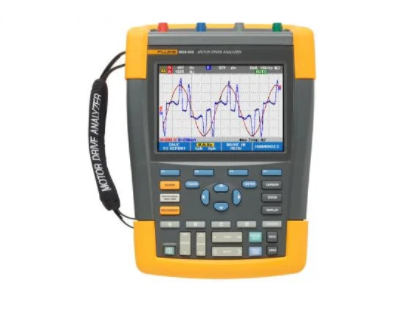

Fluke MDA-510 and MDA-550 Motor Drive Analyzers

Fluke MDA-510 and MDA-550 Motor Drive Analyzers are portable motor-drive analysis test equipment that assist in safely locating and troubleshooting common problems on inverter-type motor-drive systems. The Fluke MDA-550 and MDA-510 analyzers save time and minimize the burden of setting up complex measurements, while also simplifying troubleshooting. Simply select a test, and the step-by-step guided measurements will show you where to connect voltage and current, while the preset measurement profiles will ensure that you capture all of the data required for each critical motor-drive section—from input to output, the DC bus, and the motor itself. The MDA-500 Series covers basic to sophisticated measurements, and with a built-in report generator, you can confidently provide as-found and as-left reports.

One of the MDA-550’s notable characteristics is its ability to evaluate motor shaft voltage. This function examines the electrical discharge in motor bearings and provides both qualitative and quantitative results. The ability to quantify the amplitude and frequency of the discharge enables prompt diagnosis of motor bearing issues. This is an essential function since bearing discharges can cause early bearing failure, resulting in costly downtime and repairs. Multiple functions into a single instrument, decreasing the number of tools required for the activity. This is a huge breakthrough, as previously, a technician would have to bring a multimeter, an oscilloscope, and a power analyzer to a service call. The MDA-550 simplifies this by combining all of these features and more into a single device.

Features

The MDA-510 and MDA-550 are appropriate portable motor-drive analysis test equipment for safely locating and troubleshooting common faults with inverter-type motor-drive systems.

- Measure essential motor-drive characteristics such as voltage, current, DC Bus voltage level and AC ripple, voltage and current unbalance and harmonics (MDA-550), voltage modulation, and motor shaft voltage discharges.

- Measure extended harmonics to determine the effects of low and high order harmonics on your electrical power system.

- Guided measurements for motor-drive input, DC bus, drive output, motor input, and shaft measurements (MDA-550) are performed using graphical step-by-step voltage and current connections.

- Use a streamlined measurement setup with preset measurement profiles to automatically collect data based on the test technique you’ve chosen.

- Create reports quickly and easily, ideal for recording troubleshooting and collaborative work with others.

- Measure more electrical characteristics on industrial systems using full 500 MHz oscilloscopes with metering and recording capabilities.

In summary, the Fluke MDA-510 and MDA-550 Motor Drive Analyzers offer a comprehensive, user-friendly, and portable solution for motor drive troubleshooting, contributing to increased efficiency and reduced downtime in various industries.